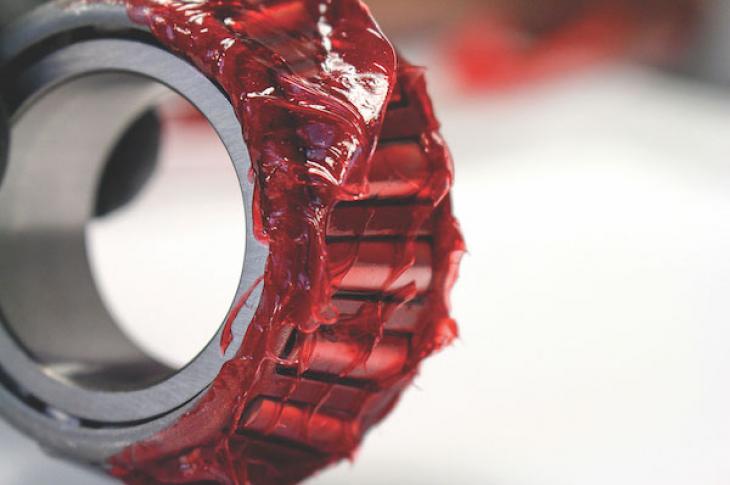

Temperature, rotate speed, load factors usually determines the use type and characteristics of grease. There are various lubricant greases used in different industries, such as the lithium grease, MP3 grease, extreme pressure grease, high temperature grease, etc. Lubricant grease has the functions of reducing mechanical friction, prevent metal aging and prevent air leakage, oil leakage, water leakage, etc

When selecting the lubricant grease, you can consider the following factors:

Work temperature has a great influence on lubricant grease, if the environment and mechanical operation temperature are high, should select the high temperature grease.

2.Rotate Speed

The high speed running parts has high temperature and fast temperature rising, which cause the loss of lubricating grease. In such a situation, High Viscosity Lubricating Grease shall be selected.

3.Load

The cone penetration of grease is related to the load during operation, when the load is heavy, we should use the grease with small cone penetration. When bearing both the heavy load and impact load, we should use the grease that contains extreme pressure additives, such as the EP Grease.

Select the different grease according to the different working environment. In the humid environment, grease with strong water resistance should be selected. The Molybdenum Disulfide Grease ( MoS2 grease) should be used.

According to the actual situation and environment, select the the appropriate grease type, ensure the grease play the best lubricant effect.

On August 21, 2023, MIMSAutomobility Moscow will be grandly opened at the Moscow Ruby Exhibition Center. The exhibition is a professional event with the highest degree of internationalization, the largest scale and the widest range of products in the automotive industry in Russia and the CIS region. In 2022, MIMS has an exhibition area of…

06

2023.07

Lubricating grease is a kind of oil which is made of base oil, thickener and additive in a certain proportion.The main function of grease is lubrication, protection and sealing.The shelf life of grease is generally 3 ~ 5 years, or even longer.The shelf life of different types of butter is different.In order to ensure the…

30

2023.06

Submit Request