The editor of the previous issue introduced the composition and main functions of bearing grease. This issue will then introduce in detail how to select bearing grease. Different bearings require different greases, and the greases used under different working conditions are also different.

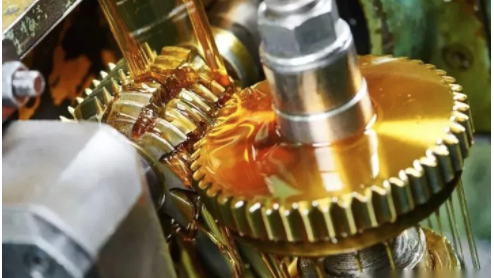

In order to form the required oil film thickness, the lubricant must have a certain viscosity at working temperature. The viscosity of the lubricant decreases with the increase of temperature. Therefore, we should choose the lubricant with higher viscosity when the working temperature is high, , and when the working temperature is low, we should choose the lubricant with lower viscosity.

When the load of the bearing is large and the speed is low, the consistency of the bearing grease should be larger, and the viscosity of the base oil should be larger. On the contrary, we should select the products with larger cone penetration ;

Bearings working in wet environment should choose grease with good corrosion resistance. The machinery working in a humid environment needs to stay for a long time. After staying, the bearing surface will form condensed water due to cooling. In order to prevent rust, we had better select the non-absorbent calcium base grease. When the bearing around the dust, and the use of curved seal, in orde to make the bearing grease play a sealing role,then should choose the grease with less penetration.When the bearing medium has a strong chemical effect, should choose the grease with anti-corrosion additives.

Lubrication bearings, grease painted the more the better, which is a common misunderstanding. Excessive grease in the bearing and bearing chamber will cause excessive stirring of grease, resulting in extremely high temperature. The amount of filling lubricant for rolling bearings should be 1 / 2 ~ 1 / 3 full of bearing internal space, and should be 1 / 3 at high speed.

We can 't mix with old grease when using new grease, even the same type. Because the old grease contains a large number of organic acids and impurities, mixing with the new grease will accelerate its oxidative deterioration. Therefore, when changing grease, you must clean the old grease on the parts, and then add new grease.

After choosing the correct grease, we should also use it correctly. If the amount of fat is too large or too small, it can not achieve good results. When storing, we should try to store it indoors to avoid the sun and rain. If stored properly, it may cause problems such as discoloration or oil separation.

Our recommended bearing lubrication products:

If you want to know more about product lubrication solutions or related questions about grease color, or you have any questions, please online consultation ! Dongsen customizes appropriate sample tests and solutions for your products.

Dongsen Grease is widely used in various industries

Comprehensive lubrication service scheme

While solving your equipment lubrication problem

Enjoy the best lubrication service

We must be your best choice.

Welcome to contact our sales staff for consultation and provide free sampling.

On August 21, 2023, MIMSAutomobility Moscow will be grandly opened at the Moscow Ruby Exhibition Center. The exhibition is a professional event with the highest degree of internationalization, the largest scale and the widest range of products in the automotive industry in Russia and the CIS region. In 2022, MIMS has an exhibition area of…

06

2023.07

·Bearing grease-bearing service life of the ‘ blood ‘ * * Bearing grease is a widely used lubricant.It is often used in bearing repair and maintenance to ensure the normal operation of the running parts of the equipment. It is also an important factor affecting bearing life. Bearing grease consists of base oil, additives, and…

27

2023.03

1.Excessive bearing grease will not only fail to lubricate, but also have many negative effects. – – Taking bearings as an example,add excessive bearing grease, which will lead to increased bearing rotation resistance, increased temperature and energy consumption, and increased temperature will also cause grease oxidation,Speed up ( early deterioration, oil service life is shortened…

23

2023.03

Submit Request